CO₂ Laser Technology Advancing Precision in Industries

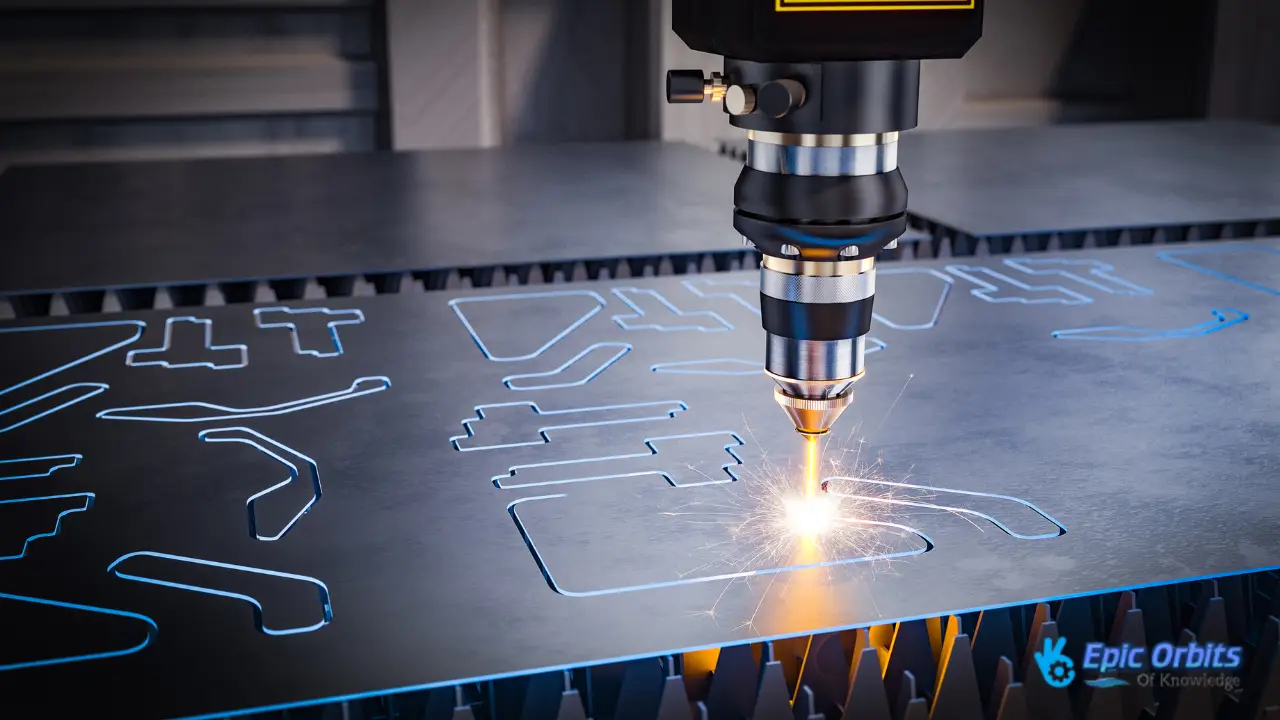

CO₂ lasers are powerful tools that emit infrared light for precise cutting, engraving, and welding across various industries.

Eighty percent of industrial enterprises in the United States use CO₂ laser technology. This evidence demonstrates the need for exact cutting and engraving. Key in many different disciplines, the CO₂ laser performs well on metals, polymers, and ceramics. Thanks to technology developments, its strong beam lets you mark with unparalleled precision and flexibility.

Knowing the Principles of CO₂ Laser Technology

The CO₂ laser machine operates at a 10,600 nm wavelength. This capability makes cutting and engraving various materials ideal. Key knowledge is understanding of how it operates. It covers the beam delivery system, laser tube, and power supply.

Non-invasive is a CO2 laser therapy akin to fractional CO2 laser. The skin looks younger with the CO₂ laser equipment. It increases collagen, thus smoothing the skin and lessening wrinkles.

For fine lines and wrinkles as well as other aging symptoms, this therapy is excellent. Those middle-aged and older individuals with moderate to severe skin problems would benefit most from it. For individuals with lighter complexions, however, it's safer to prevent hyperpigmentation and other negative effects.

Industrial CO₂ Laser Applications: Evolution

Industries like automotive, electronics, and pharmaceuticals have benefited from CO₂ laser technology. It allows producers to cut, ablate, and laser engrave on many materials. Offering both ablative and non-ablative treatments, it is also utilized for skin tightening.

Fractional lasers created by CO₂ laser technology aid in skin renewal and scar reduction. Great accuracy in healing damaged tissue is achieved with the UltraPulse Encore by use of “microbeams.”

When treating skin problems like angiomas and superficial pigmented lesions, the CO₂ laser is a first option. Key in dermatology, it is well-known for exact and safe ablation. Research supporting its efficiency will probably make the CO2 laser indispensable in both sectors and medicine.

| Application | Description |

|---|---|

| Laser Engraving | Using a CO₂ laser to engrave materials |

| Laser Ablation | Using a CO₂ laser to remove material |

| Skin Tightening | Using a CO₂ laser for skin tightening and rejuvenation |

Fundamental parts of a CO₂ laser machine

Parts of CO₂ laser machines cooperate to create anything. They are essential for applications like laser skin resurfacing and other CO₂ laser technology usages.

A CO₂ laser machine consists of many really crucial components. These include control interfaces, power supply systems, cooling systems, and beam delivery choices. Every component is very vital for the operation of the machine.

- Systems of power supply that meet the required energy for the laser to run.

- systems of cooling that stop overheating and preserve the best performance.

- Beam delivery choices give one exact control over the laser beam.

- Control interfaces let users change parameters and track machine running state.

Users of CO2 laser equipment may maximize their outcomes by knowing the main components. This concept holds true for laser skin resurfacing as well as for other jobs like cutting and engraving.

Maximizing Accuracy in CO₂ Laser Cutting

In industry, CO₂ laser technology has revolutionized everything. It presents great accuracy and precision. Understanding the operation of a CO₂ laser machine can help you to acquire the greatest outcomes.

CO₂ lasers have 1-5 mm varying beam diameters. They are then focused down to 0.25 mm to 0.025 mm. Special lenses and methods are used in doing this.

Laser cutting tools enabled by this technology allow tiny cuts as small as 1/10,000th of an inch. That's less than human hair. These ideas can help you to increase accuracy:

- For more precise cuts, lower the heat-affected zone (HAZ).

- Change the cutting speed to prevent either excessive heat or insufficient energy.

- Adjust parameters for many materials.

- Verify accurate alignment of mirrors in the machine.

Understanding the operation of a co-existence laser machine enables producers to produce superior goods. In sectors like automotive and aerospace, where accuracy counts greatly, such knowledge is very vital.

From 1000 to 2000 watts of power may be used by laser cutting equipment. One may find the concentrated beam spot size as little as 25 microns. Unmatched accuracy and precision are possible with the correct CO₂ laser technology and equipment.

Modern CO₂ Laser Applications for Manufacturing

The production environment has been transformed by the CO₂ laser. It produces very precise, difficult items. It is essential for manufacturers, as it can precisely label little objects.

This technology enables creators to produce complex designs and patterns. It marks and etches surfaces as well as cuts and engraves. From common goods to medical equipment, this feature makes numerous things possible.

One benefits much from using CO₂ laser tech. It works rapidly, can be repeated, and gives accuracy. The narrow beam of the laser reduces damage and contamination, therefore producing precise and smooth engravings.

It may also fast mark internal codes or serial numbers. This feature increases the speed of production and efficiency.

Best Practices and Safety Procedures

Using CO₂ laser treatment and therapy calls for rigorous safety guidelines. CO₂ laser classification by the Center for Devices and Radiological Health (CDRH) falls under Class 4. They pose a great threat to skin and eyes.

Following a few rules helps one to be safe. The procedure involves acquiring correct training and donning the appropriate protection gear. Following these important safety precautions can help:

- Using gloves and protective eyewear.

- Ensuring appropriate ventilation helps to stop particle inhalation produced by lasers.

- Annual audits and staff training are conducted using a laser safety officer (LSO).

Following Z136.3 recommendations for the safe use of lasers in healthcare set by the American National Standards Institute (ANSI).

Furthermore, important is knowledge of the CO2 laser treatment and therapeutic hazards. Among them are the risk of fires and the requirement of proper laser cutter arrangement and maintenance. Following these safety precautions helps us lower the CO₂ laser running dangers.

Maximizing CO₂ Laser Performance across Various Materials

Using a CO2 laser machine requires an understanding of the characteristics of the material. Regarding skin tightening, safe and efficient therapy depends on certain parameters. One should take careful thought on material thickness, density, and heat conductivity.

Processing both metal and non-metal is perfect with the CO₂ laser machine. Because of their great density and heat conductivity, metals need certain settings. Different settings are needed for nonmetals such as leather, acrylic, and wood to prevent overburning or insufficient cutting.

Key elements influencing CO₂ laser performance consist of:

- Density and thickness of materials.

- Heat flow and thermal conductivity.

- Settings in laser strength and frequency.

- Accelerations and cutting speed.

Better outcomes may follow from an awareness of these elements and modification of the machine parameters. The lifetime of the equipment also depends on routine maintenance and lens, mirror, and ventilation system cleaning.

The ideal parameters for cutting many materials are listed here:

| Material | Power Setting | Frequency Setting | Cutting Speed |

|---|---|---|---|

| Wood | 50-70% | 100-200 Hz | 10-20 mm/s |

| Acrylic | 30-50% | 200-300 Hz | 5-10 mm/s |

| Leather | 20-30% | 100-200 Hz | 5-10 mm/s |

Users may maximize results and extend the lifetime of their equipment by following these recommendations and modifying the CO₂ laser machine parameters.

Maintenance and Troubleshooting of Your CO₂ Laser System

Maintaining the best shape of your CO₂ laser system is critical. Quick solutions and regular maintenance help to prevent issues before they occur. Here's how to keep your system humming:

To prevent power loss and alignment issues, CO2 laser tech requires cleaning and maintenance. Eighty percent of power loss is caused by dirty optics; misalignment reduces efficiency by thirty percent. A requirement is regular inspections and repairs.

Every day, clear the workspace, empty the trash tray, and check mirrors and lenses. Weekly chores include wire inspections, exhaust checks, and mirror washing. Oil the guiding rails and beds every two weeks.

For more troubleshooting advice:

- Please inspect the laser tube for any damage.

- Check the water cooling system.

- See the air assist for obstructions.

- Check the mainboard's and power supply's capabilities.

Your CO2 laser system will function faultlessly if you follow these maintenance and troubleshooting guidelines. Less downtime and more work completed follow from this. Always refer to the handbook for your system to find particular care and fixing guidelines.

Innovative Uses in Contemporary Manufacturing

These days, CO₂ laser technology finds use in numerous disciplines, including automotive components, medical equipment, and aircraft. It facilitates exact cutting and difficult form building. The technique is thus fundamental in many spheres. In the aerospace industry, for instance, it facilitates the creation of lightweight yet robust aircraft components.

One gains various advantages from using CO₂ laser equipment. Some of them include:

- Great accuracy and consistency.

- Rapid periods of manufacturing.

- Little material waste.

- Capability to carve intricate shapes.

In medical devices, it manufactures implants and surgical equipment fast and precisely. By reducing additional stages required, it also increases vehicle part manufacturing.

Many sectors now benefit from the CO₂ laser machine. It has enabled the development of fresh and creative items. Future applications of CO₂ laser technology will be increasingly more evident as technology develops.

Cost-benefit study of CO₂ lasers use

Before using coordinated laser technology, one should begin with a cost-benefit study. ining the cost of the equipment, maintenance, and how it increases production, this study shows that for precise tasks, such as scar healing and extra tissue removal, CO₂ lasers are fantastic.

Although CO2 laser gear is expensive, the advantages exceed any expense. It makes work more exact and effective. It also reduces physical effort, which over time helps us save money. Important factors to consider are

- The initial investment in CO₂ laser equipment is significant. is significant.

- The continuous expenses of keeping and fixing the machinery constitute maintenance.

- Rising productivity and efficiency brought about by CO₂ laser technologies suggest promise.

Businesses may determine if CO2 laser technology is right for them by balancing these factors. For many businesses, it is a wise decision, as it provides numerous advantages and may help them save money.

Prospective Development in CO₂ Laser Technology

CO₂ laser technology has promising futures. Used in many disciplines, including healthcare, it has become increasingly flexible. For instance, it's utilized non-surgically for skin tightening.

- Some important patterns include.

- less environmental effect and more efficiency.

- Improvements in power supply efficiency lead to reduced energy consumption.

The integration of artificial intelligence and machine learning into laser marking enables the automated identification and adjustment of focus points.

The CO₂ laser industry is quickly expanding. In 2023 it is worth USD 3.43 billion; by 2032 it could reach USD 6.14 billion. Thanks to enormous demand, the Asia-Pacific area is driving this expansion.

Among the many applications of CO₂ lasers is skin tightening. Future applications will be much more evident as research and development continue to improve.

| Market Segment | 2023 Value | 2032 Projection |

|---|---|---|

| Global CO₂ Laser Market | USD 3.43 billion | USD 6.14 billion |

Conclusion

From manufacturing precisely to supporting medical disciplines, CO2 laser technology has transformed several sectors. It achieves great efficiency and precision by utilizing focused light. This feature is therefore very helpful in many procedures.

The future of CO₂ laser technology is really promising. It will generate fresh and fascinating applications. The topic covers improved aircraft engineering, cutting-edge medicinal treatments, and fresh approaches to manufacturing.

For companies striving to lead, CO₂ lasers will remain a main instrument. They enable quicker, more precise, and better products. More advancement and fresh ideas in many spheres follow from this.