How 3D Printing Is Revolutionizing Engineering Practices

Explore the impact of 3D Printing, Engineering advancements in current practices. Stay updated on the latest trends and analysis.

With the printing press invented by Johannes Gutenberg in the middle of the fifteenth century, knowledge spread and entered a new chapter. Another revolutionary invention surfaced at MIT laboratories over 500 years later: 3D printing, also referred to as additive manufacturing. By layering materials, this technique offers previously unheard-of design flexibility and manufacturing capability, therefore enabling the development of sophisticated three-dimensional things from digital data.

From fast prototyping to the manufacturing of end-use components, 3D printing has revolutionized engineering methods in several sectors. This approach reduces waste and helps create intricate shapes previously unattainable by adding material only where required. Therefore, 3D printing disrupts engineering processes, enabling faster innovation cycles, cost savings, and new design possibilities.

What is the concept of 3D printing?

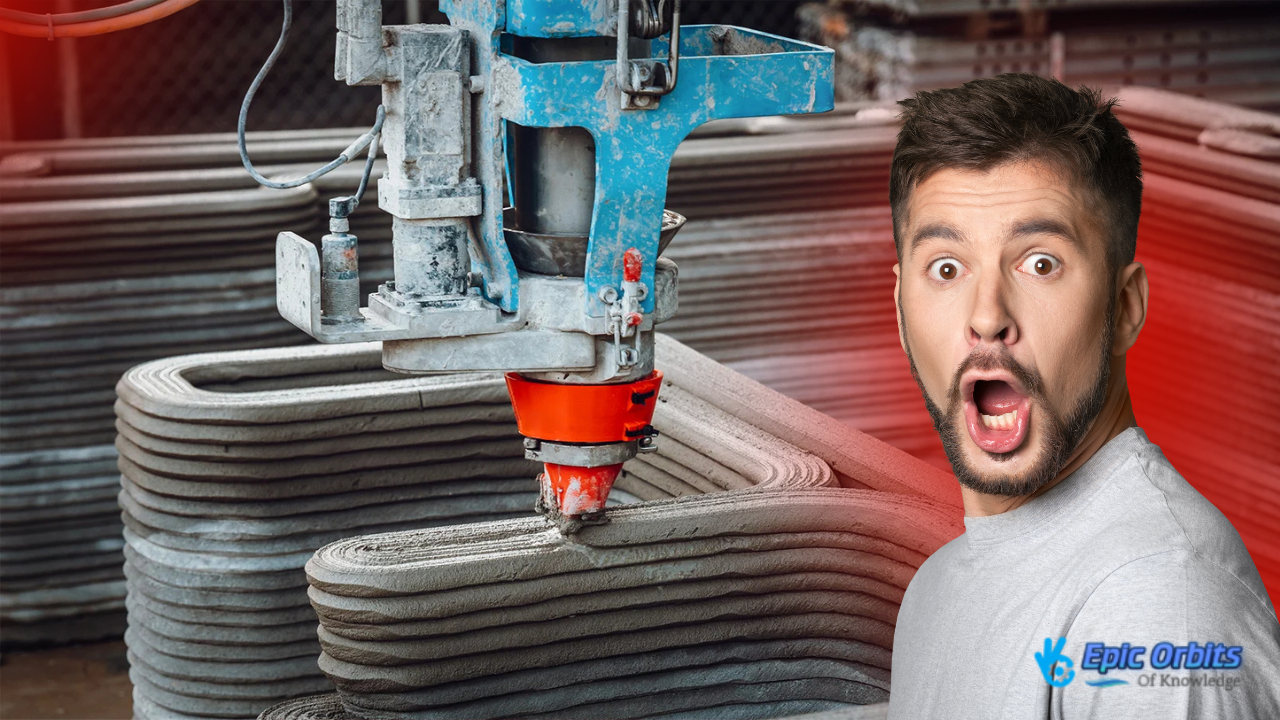

Manufacturing a tangible three-dimensional item, a solid thing from a virtual model, is accomplished via 3D printing. Unlike other manufacturing methods, which produce a product from a stock by eliminating the undesired material, three-dimensional printing is different. Built in layers at a time, components like plastic, metal, or resin are added consecutively until the whole item is generated.

This process enables the creation of various geometries and designs for buildings that would be realistically difficult or even unfeasible using traditional building techniques. Since 3D printing is digital, designers and engineers may create a CAD model, change the design if needed, and then immediately send the design file for manufacturing to the printer. From aerospace and automotive to health care to even consumer items, this simplified approach finds application in many different fields.

3D Printing’s Evolution in Engineering

The arrival of 3D printing has transformed the engineering scene, changing the design, prototyping, and manufacturing techniques. Significant technological and material developments throughout this evolution have made it possible to create sophisticated buildings and components with formerly unheard-of accuracy.

1. From Rapid Prototyping through Manufacturing Revolution

Rapid The engineering road map for this medium began with rapid prototyping, which used 3D printing to rapidly produce model components. It evolved into a fully developed manufacturing process that is able to generate end-use components. By streamlining the 3D printing technique, researchers such as John Hart at MIT have been instrumental in this change. Hart’s team investigated the extrusion process—a typical technique in 3D printing—to grasp its basic constraints, including heating polymers, applying force, and printhead speed.

Recognizing the limitations of existing 3D printing technologies, Hart and his colleagues developed a new printer that operates 10 times faster than previous models. For instance, a gear that previously took one to two hours to print can now be produced in just five to ten minutes.

Several technological breakthroughs have driven this progress in additive manufacturing. Advances in materials science have expanded the industry beyond basic plastics to include advanced polymers, composites, ceramics, and metal alloys, broadening engineering applications. Metal 3D printing technologies, such as SLM and DMLS, enable the creation of complex metal parts that were impossible to manufacture using traditional methods. Improvements in printer hardware, including enhanced precision, speed, and reliability, have addressed early limitations and allowed for faster, more efficient production.

These innovations have transformed additive manufacturing from a niche technology into a widely adopted production technique, supported by ongoing advancements in materials, printing technologies, and software capabilities.

- Modern polymers and metal alloys are among the printed materials that material advancements have widened the spectrum for.

- The evolution of metal 3D printing has presented fresh opportunities for the manufacture of intricate components.

- Generative design and topological optimization of software help engineers to produce optimal constructions.

Engineer Transformational Benefits from 3D Printing

Offering hitherto unheard-of advantages, 3D printing is changing the engineering terrain. Engineers designing, prototyping, and manufacturing components now use this technology to reach a degree of complexity and customization never possible in past years.

- Increased Complexity and Design Freedom: The greater design flexibility 3D printing provides is one of its most important benefits. With conventional manufacturing techniques, engineers can now make intricate geometries and structures that were either impossible or too expensive. This independence helps us produce creative goods with better performance and utility.

- Prototyping and iteratively accelerating cycles: By speeding up the prototyping process, 3D printing enables engineers to quickly test and iterate their innovations. This rapid prototyping capability enables companies to bring their products to market faster, reducing the time and costs associated with product development. Its use in prototyping also enables the creation of functional prototypes ready for testing and validation.

- Saving Money and Maximizing Resources: Adoption of 3D printing can result in major manufacturing cost savings. Companies may save initial expenses by doing away with tooling and molds. Additionally, 3D printing enables the production of components on demand, thereby reducing inventory costs and waste generation. This kind of manufacturing uses resources more wisely and could result in major savings.

- On-Demand Production and Customizing: Mass customization made possible by 3D printing lets one produce tailored goods at scale free from major cost penalties. Applications where anatomical fit is crucial—like those involving medical implants and prostheses—are where this skill is especially important. On-demand manufacturing, made possible by technology, also lets businesses react quickly to consumer wants, thereby lowering the necessity for inventory storage.

Innovative uses of 3D printing in engineering disciplines

The development of 3D printing technology has revolutionized several technical disciplines and made hitherto unheard-of possible advancements possible. Many different fields are using this technique to increase productivity, lower expenses, and produce intricate patterns previously unattainable in cost.

- Automotive and aerospace engineering innovations: By allowing the manufacture of lightweight, sophisticated components, 3D printing is transforming the aerospace and automobile sectors. Using sophisticated industrial 3D printers with IDEX technology, companies are doubling their output without raising equipment costs.

- Bioengineering and Medical Breakthroughs: 3D printing is making major advances in the production of customized prostheses, implants, and surgical models, among other medical and bioengineering applications. Perfect duplication of intricate biological structures made possible by technology improves patient care and treatment results.

- Nanoscale Manufacturing and Modern Materials: The possibilities in engineering are growing as improved materials and nanoscale 3D printing evolve. Driving innovation in sectors like electronics and energy storage, researchers are investigating novel materials and methods to build structures with hitherto unheard-of characteristics.

- Tooling solutions and industrial manufacturing: Industrial producers are increasingly using 3D printing for jigs, fixtures, production tooling, and end-of-arm tools. Customized tools on demand made possible by this technology help to lower lead times and increase manufacturing efficiency by means of their availability. Using 3D-printed tools and fixtures, companies like Volvo and Volkswagen are improving their production lines.

Finally, by offering creative ideas, raising production, and allowing the fabrication of intricate designs, 3D printing is revolutionizing several technical disciplines. The predicted widening use of technology as it develops will propel developments in many different sectors.

3D printing technology’s future in engineering

Its rapid developments are reshaping the future of engineering. Collaborative projects, such as the MIT Center for Advanced Production Technologies (APT), are accelerating the acceptance and innovation of this technology.

Emerging technologies like multi-material jetting and continuous liquid interface production (CLIP) are significantly improving print speeds and material possibilities. This breakthrough is likely to have a significant influence on the sector, as it solves important restrictions that have limited industry Also notable is the inclusion of artificial intelligence and machine learning in the 3D printing process.

printing process. From real-time monitoring systems guaranteeing print quality and consistency to generative design techniques producing ideal structures, these developments are ready to transform the engineering scene.

The confluence of 3D printing and other advanced technologies, such as robots, IoT sensors, and augmented reality, is also leading to the development of new hybrid manufacturing techniques. Combining the benefits of additive and conventional manufacturing, these techniques produce novel items with unheard-of performance qualities.

Engineers will gradually design products specifically for additive manufacturing as the technology evolves. This transition is projected to result in entirely new product categories as well as a basic overhaul in the design, manufacturing, and distribution of physical items.

Analysts expect 3D printing’s share of global production to increase from about 1% to more than 10% over the next ten years. Industry analysts see the potential of this technology as promising, as its adoption represents a paradigm shift in the engineering sector.